The Builder+PLUS module is responsible for creating and maintaining the Bill of Material for an item. Builder+PLUS is the heart of your configuration management system. Items are created and maintained in Itemizer+PLUS. The items include parts, drawings, tooling, mechanical specifications, electrical specifications and pictures among others. The reason for specifying all of these items is to enable Builder+PLUS to provide comprehensive revision control over these entities.

The two major functions of the Builder+PLUS module are Revision Control and maintaining Bill of Material structures.

Revision Control / Engineering Change Order

Revisions are used primarily to control the relationship between items. Items may, however, have revisions without an associated relationship. Revisions are controlled by a uniquely numbered change document, typically a design or engineering change order. This change order may be associated with one or more item revisions.

The use of revisions and change orders is best understood with an example. Consider the following:

Item XX consists of two parts, a specification, a drawing and a tool. The revision linking all of these items to Item XX is Revision A. The change number or engineering change order is 100.

A proposed product improvement change would replace Part 2 with Part 3. If Part XX is still form fit and functionally interchangeable with Part 3, then the revision of Part XX may be increased. If the change violated any of the interchangeability rules, then a new item number must be created. Click "Next" to see the result of this change.

Item XX| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr |

|---|---|---|---|---|

| Part 1 | A | 100 | ||

| Part 2 | A | 100 | ||

| Specification | A | 100 | ||

| Drawing | A | 100 | ||

| Tool | A | 100 |

The following example shows the effect of the change. Part 2 has been taken out at revision B and Part 3 has been added.

Item XX| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr | |

|---|---|---|---|---|---|

| Part 1 | A | 100 | |||

| Part 2 | A | B | 100 | 200 | Part 2 Removed |

| Part 3 | B | 200 | Part 3 Added | ||

| Specification | A | 100 | |||

| Drawing | A | 100 | |||

| Tool | A | 100 |

The following is a more complex example to illustrate cross product change control starting out with Item XX from the previous example:

Revision Example #2Item YY is the same as Item XX with the exception of Part 7:

A decision is made to replace Part 2 with Part 3 for product cost reasons, wherever it is used. Click "Next" to see the result of this change for Item XX and YY:

| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr |

|---|---|---|---|---|

| Part 1 | A | 100 | ||

| Part 2 | A | 100 | ||

| Specification | A | 100 | ||

| Drawing | A | 100 | ||

| Tool | A | 100 |

| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr |

|---|---|---|---|---|

| Part 7 | C | 300 | ||

| Part 2 | C | 300 | ||

| Specification | C | 300 | ||

| Drawing | C | 300 | ||

| Tool | C | 300 |

This change results in the following for Item XX and YY:

Click "Next" to see the result of an ECO number lookup for change 400.

| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr |

|---|---|---|---|---|

| Part 1 | A | 100 | ||

| Part 2 | A | B | 100 | 400 |

| Part 3 | B | 400 | ||

| Specification | A | 100 | ||

| Drawing | A | 100 | ||

| Tool | A | 100 | ||

| Part 1 | A | 100 |

| Item Nbr | In Rev | Out Rev | In Chg Nbr | Out Chg Nbr |

|---|---|---|---|---|

| Part 7 | C | 300 | ||

| Part 2 | C | D | 300 | 400 |

| Part 3 | D | 400 | ||

| Specification | C | 300 | ||

| Drawing | C | 300 | ||

| Tool | C | 300 |

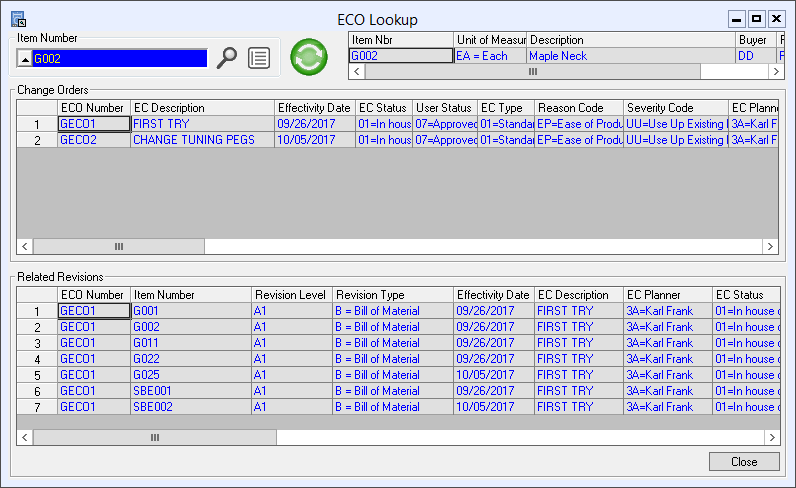

The AMAPS+PLUS ECO look-up feature would display for Change 400.

| Parent Item | Component Item | In Rev | Out Rev |

|---|---|---|---|

| Item XX | PART 2 | B | |

| Item XX | PART 3 | B | |

| Item YY | PART 2 | D | |

| Item YY | PART 3 | D |

ECO Lookup

This consolidated view shows the effect of a change across multiple products. It answers the question "I changed it here-where else did it change?"

Another use of this capability is the creation of a bill of material for a new product. If the same change number is used, then it is easy to see all of the changes that went into the creation at one time.

These product revision capabilities are further enhanced through the use of Doc-Link. The detailed textual data for each change order and revision can be conveniently stored and retrieved by Doc-Link.

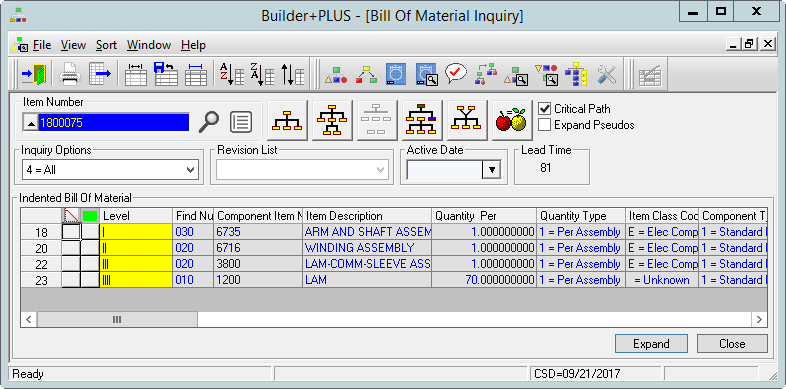

Bill of Material Maintenance

There are seven major features related to Bill of Material Maintenance within the Builder+PLUS module:

- Substitute part control

- By-product/co-product support

- Mass change with revision level control

- Critical path

- Run-out calculations

- Automated BOM comparisons

- Scrap and shrinkage